Blending a Whiskey, Building a Brand

SUBSCRIBERBringing in a blender, even on a contract or part-time basis, can help a small distillery elevate its whiskey and create a more consistent program.

56 articles in this category

Bringing in a blender, even on a contract or part-time basis, can help a small distillery elevate its whiskey and create a more consistent program.

The enormous variety in liqueurs from various countries and traditions offers distillers an opportunity to create one-of-a-kind cask-finished whiskeys.

Changes in barrel sizes, warehousing, and entry proof have all altered the character of the whiskeys we make and enjoy today. Those old practices also may be sources of inspiration for craft distillers who want to make distinctive products.

Much like the debate over on-grain or off-grain fermentation, the distiller’s choice on whether to boil their American single-malt wort has a range of consequences for flavor and efficiency.

Craft distillers are elevating unaged whiskey as a pure, transparent expression of the distiller’s craft and the farmer’s grain.

There’s an important fork in the road to creating an American single-malt whiskey: Will you produce it on-grain or off-grain? That single decision has a major impact on the whiskey’s character, the equipment you’ll need, and the shape of your waste streams.

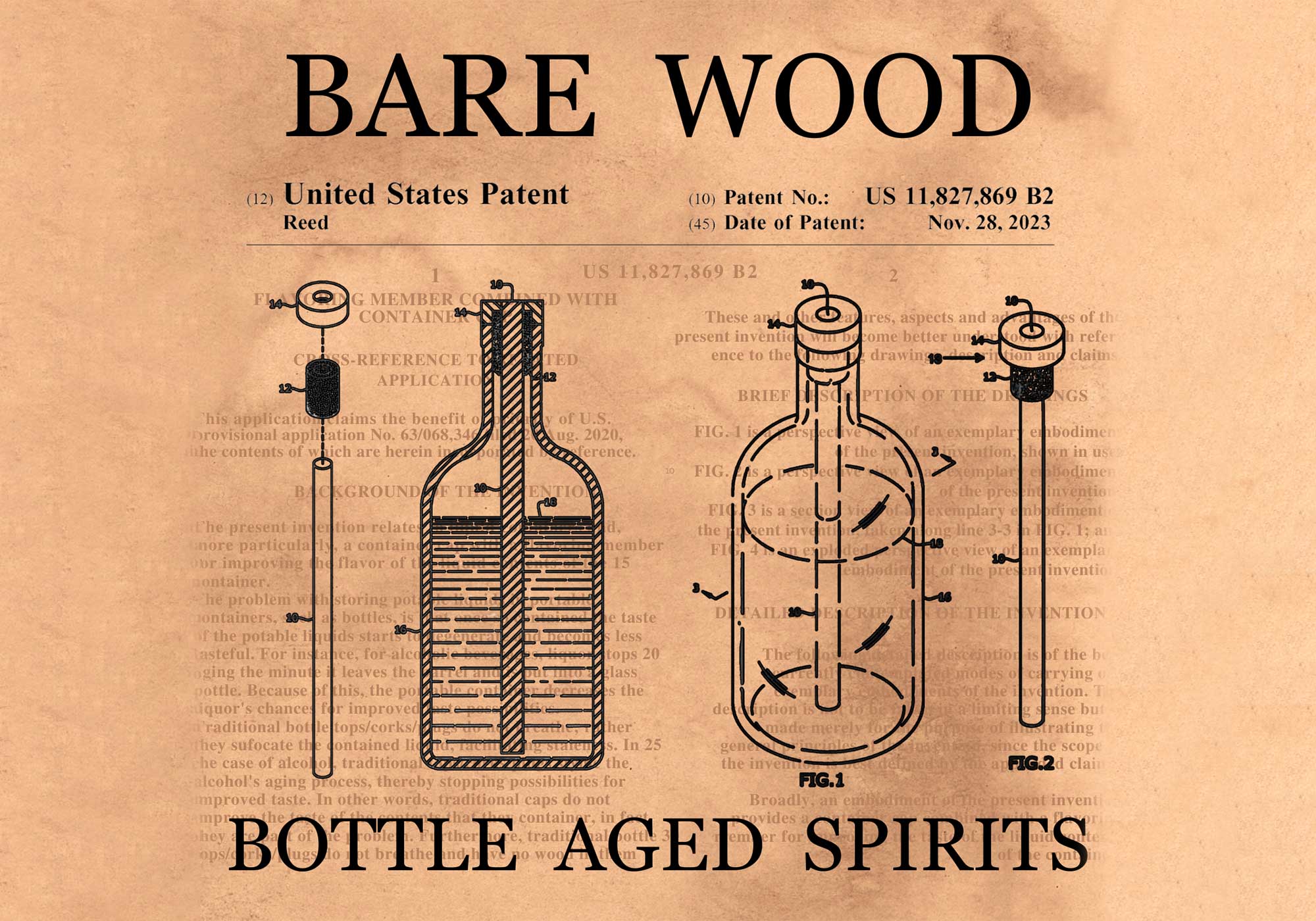

That submerged chunk of wood is a message in the bottle: To customers, it might communicate wider variety, better sustainability, or a new way for them to engage in the aging process at home.

In this clip from their video course, head distiller Ryan Scheswohl describes Village Garage’s on-grain, open-top fermentation method, from how many days they allow for the ferment to their streamlined transfer into the still.

American craft distillers have adapted an Old World practice for their varied production environments.

As distillers in western Pennsylvania work to define their own style of rye, historical examples and modern efforts guide the way. It’s a project that could be instructive to distillers in other regions with distinctive styles.

This unusual rye-wheat hybrid isn’t well known among the drinking public, but its star may be rising in the world of craft whiskey.

Distilling in Florida’s hot and humid environment, and producing spirits specifically tuned for cocktails in a tourism-driven locale—those are the major guideposts for the creative direction of these sibling distilleries, as well as for their methods of barrel aging and adding flavor.

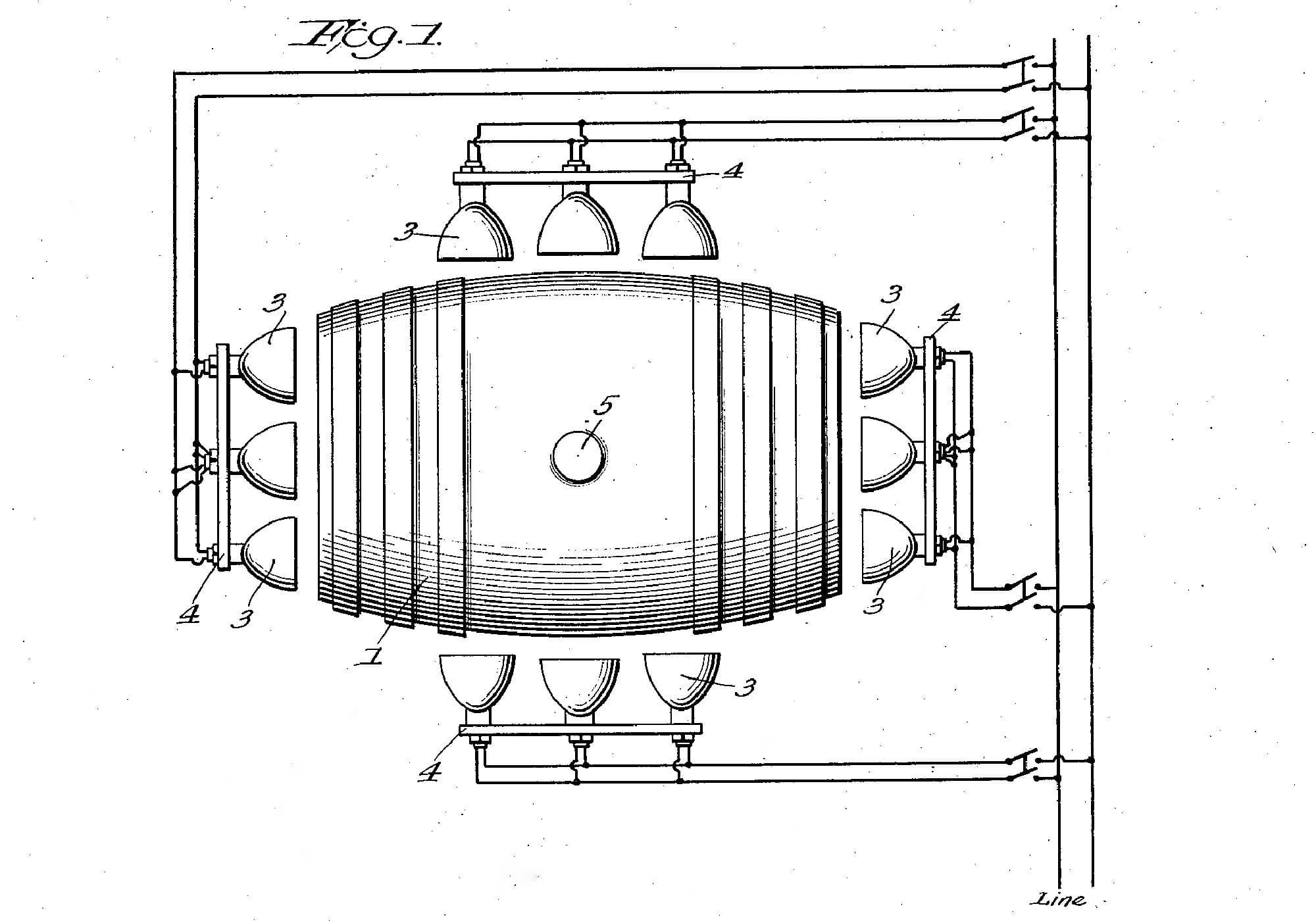

Rapid-aging research is as old as commercial whiskey production. What are the upsides, what are the downsides—and why hasn’t it taken broader hold in the industry?

The available data around flavor impacts is unclear—even contradictory—but this much we know: Distilling a range of strengths for the barrels will give you a broader range of blending options.

R&D distiller Mitch Mahar describes the innovation program that helps WhistlePig choose single-cask finishes worth pursuing, as well as potential threads for their annual Boss Hog special release.

In this clip from their video course, WhistlePig R&D distiller Mitch Mahar explains how the rye harvest can affect their choice of barrels for aging the spirit, as well as how cask placement can affect the final product.

The TTB has announced the new style designation for American single-malt whiskey—an achievement years in the making, and one that distillers expect to open new doors.

This classic cocktail is perfect for warding off the winter woes, or for just warming up.

Understanding the reactions that occur in a barrel can help distillers get the most from their cellar environment and cask choices.

While smaller vessels can speed up certain types of aging reactions, the results are uneven among different aspects of maturation. Let’s look closer at what’s happening inside those barrels.